Highlights

- Cover crop-based organic no-till soybean production was evaluated at 6 locations – 4 observational sites and 2 replicated trial sites

- At two replicated trial sites, cover crop-based organic no-till soybeans yielded 9-14 bu/acre less than those grown with standard practices. Yield reductions likely due to delayed rye crimping and soybean stand damage, respectively.

- Yields at observational on-farm sites ranged from unharvestable to 47 bu/ac. Discrepancies in success were due to: background weed pressure, ability of soybean seeding equipment to effectively cut through rye mulch, timeliness of rye flowering and adaptive management through adjustment of soybean seeding rate.

Purpose

The objective of this two-year project is to determine methods to manage a cereal rye cover crop to achieve multiple benefits, while minimizing any negative effects on crop yield. The project has two components: 1) to evaluate spring rye termination timing and its effects on nutrient uptake, weed abundance and soybean development and yield, and 2) to evaluate a cover crop-based organic (or herbicide-free) no-till soybean production system using a roller crimper to terminate cereal rye. This report includes information on the second component. For information on the first, refer to “Maximizing cereal rye cover crop management for multiple benefits: Spring termination timing”.

Cover crop-based organic no-till soybean production has been popularized by the Rodale Institute in Pennsylvania. The system uses a roller crimper, a drum with chevron-shaped metal attachments (Figure 1), which crimps the stems of rye (or another suitable plant) once it has reached anthesis and kills it. Soybeans are then typically seeded into the mulch, which, if thick enough, provides season-long weed suppression. The cover crop-based organic no-till system offers advantages in terms of labour savings and soil health improvements.

Research in states with similar climates to Ontario, including Wisconsin and New York, has found that the system can produce comparable yields to wide-row, tillage based organic soybean production. Trials have not been conducted to date in Ontario, and on-farm experiences with the system have been mixed. The purpose of this trial is to evaluate cover-crop based organic soybean production, using established best practices, across a range of Ontario soil and climate conditions.

Figure 1. A front-mounted roller crimper being used to terminate cereal rye at anthesis in Ontario, June 2019

Figure 1. A front-mounted roller crimper being used to terminate cereal rye at anthesis in Ontario, June 2019

Methods

In this trial, replicated and randomized strips were used to compare cover crop-based organic no-till soybean production with standard production practices (Table 1). Observational sites that evaluated cover crop-based organic no-till soybean production were also monitored. Cereal rye biomass, soybean population and seeding conditions, soil temperature and moisture, and soybean development and yield were measured.

Replicated and randomized strip trials

At the Drayton site, tillage was used in the control treatment to control weeds. Primary tillage was performed with fall disk-ripping and several cultivator passes in spring. Soybeans were planted on June 9th at a rate of 200,000 seeds/acre in 30” rows. Weeds were managed with one pass of a tine weeder prior to crop emergence, followed by three passes of inter-row cultivation up until canopy closure.

In the roller crimped treatment, rye was seeded on a 45-degree angle on September 14, 2018 at a 3 bu/acre rate (168 lbs/acre). Soybeans were planted into it on June 8th at Zadok stage 59 (head completely emerged) using a John Deere 750 no-till drill at 7.5” spacing and a rate of 250,000 seeds per acre. Due to crop emergence before intended crimping date, roller crimping was performed once soybeans reached the first trifoliate stage, on July 8th. There were six randomized replicates of each treatment (Figure 2).

Figure 2. Aerial view of replicated and randomized plot at Drayton site, spring 2019. Due to randomization, some strips from one replicate to the next were side-by-side.

The Elora site was a small plot trial located at the University of Guelph’s Elora Research Station (Figure 3). The control treatment did not have rye and weeds were controlled with herbicide applications. Soybeans were planted in 15” rows at a rate of 220,000 seeds per acre on June 12th across both treatments using a Kearney no-till planter. In the no rye treatment, the only tillage performed was done the previous fall. In the rye treatment, soybeans did not receive any weed control by herbicide or tillage. There were six randomized replicates of each treatment.

Observational sites

The remaining sites (Blyth, New Hamburg, St. Marys J & M) did not involve different treatments; instead, they were either full or partial fields in which cover crop-based organic no-till soybean production was attempted (Table 1). Background information was collected and average rye biomass, soybean stand and development and yield values (where possible) were measured and have been reported. By observing the system across a wide range of soil and climate conditions, it is possible to quickly identify specific challenges and determine practices that work and those that don’t.

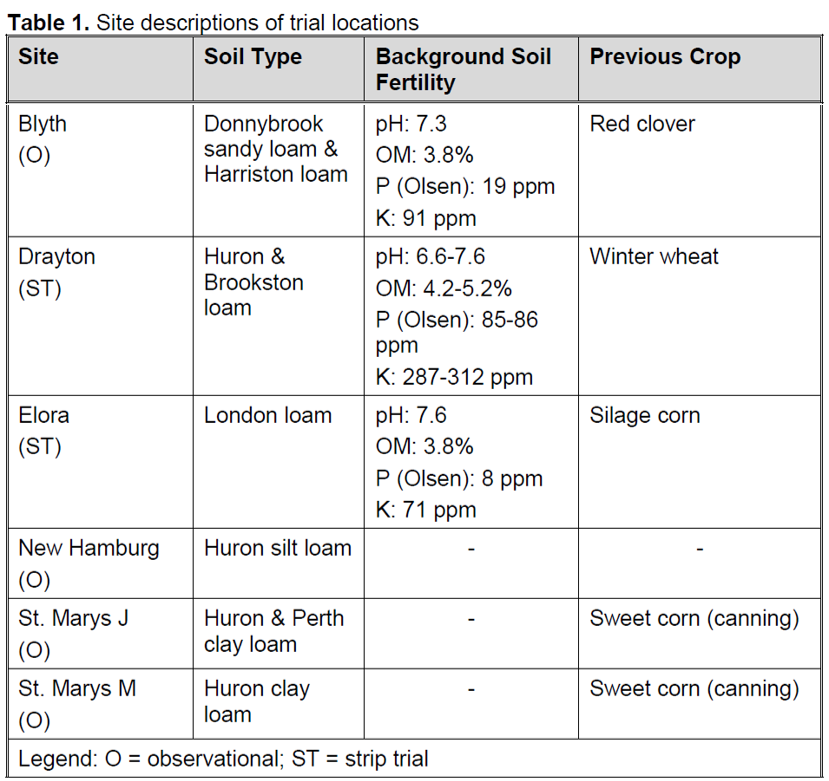

Table 1 provides background information on all sites, including soil type, background fertility

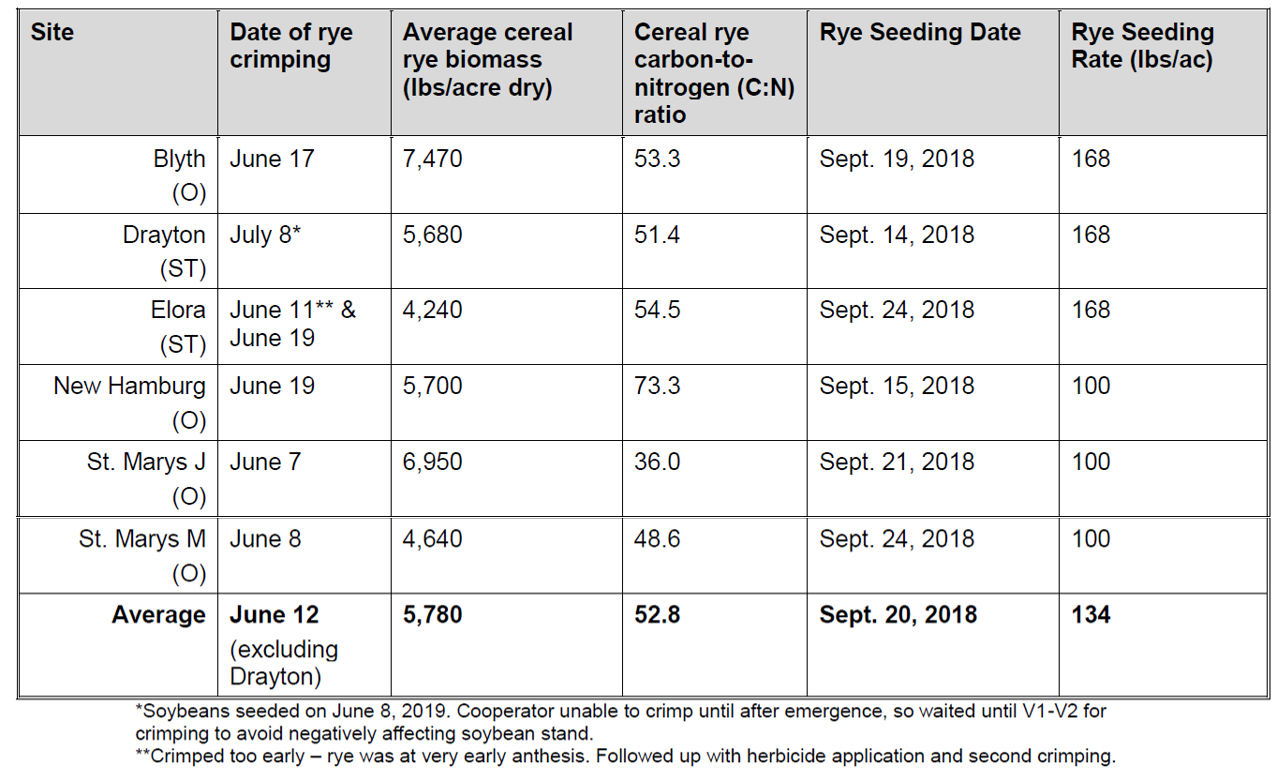

(where available), previous crop and cereal rye seeding details. At all sites, rye was seeded on an angle (> 20 degrees) relative to the direction of roller crimping and soybean seeding. As per best practice from nearby jurisdictions, rye was seeded before the end of September at a rate of 3 bushels/acre (168 lbs/acre) at the strip trial sites and Blyth (Table 2). Rye was seeded at 100 lbs/acre at the remaining sites. Common rye was used at all sites.

Site measurements and monitoring

All sites were monitored on a regular basis. At strip-trial sites, observations, measurements and samples were collected from multiple locations within each strip. At observational sites, geo-referenced locations (8-10 per field) were established and used throughout the season for data collection. Main observations and measurements included cereal rye biomass and carbon-to-nitrogen ratio at time of termination (Table 2), soybean stand (Table 3), height and growth stage (Tables 4) and soybean yield (Table 5). Soil temperature and moisture was also measured at the Elora site at 2-inch depth from April to October using sensors and automatic data-loggers (Figure 3).

Figure 3. Soil temperature and moisture sensors installed at the Elora site in four out of six replicates. Readings were logged hourly throughout the growing season.

Yield was determined by weigh wagon or by combine scale at strip trial sites plots. Yield self-reported by cooperating farmers at observational sites. Values adjusted to 13% moisture. Statistical analysis was performed on yield data. Different letters indicate a significant difference (P < 0.10).

Results

Cereal rye biomass

Across all sites, the average biomass at the time of termination was 5,780 lbs/acre of dry matter. According to research from regions such as southern Pennsylvania and North Carolina, a minimum of 8,000 lbs/acre biomass is required for sufficient weed suppression. More northern regions, however, such as upper New York state, have found 6,000 lbs/acre to be sufficient. Early spring growth is also critical for competition with weeds. The Drayton site had good early season canopy coverage (Figure 4) and reasonable biomass (5,680 lbs/ac), which contributed to excellent weed control. Below average spring temperatures likely reduced overall rye biomass.

Figure 4. Thick cereal rye stand at Drayton Site on April 30, 2019

Date of rye crimping varied by site and did not reflect exact timing of anthesis; however, June 7th was the earliest date of approximately 50% rye anthesis for any of the sites. This represents an approximate one-week delay of anthesis at the same location (St. Marys J) compared to 2018. The average temperature in both April and May of 2019 was 0-2 ⁰C below normal in southwestern Ontario, which resulted in delayed development. The average crimping date across all sites was June 12th (Table 2). It is expected that under more normal spring conditions, rye anthesis for the region will be reached between June 1st to 10th.

Rye seeding rate did not impact biomass, as the averages for both rates were practically identical (5,800 lbs/ac biomass for 168 rate and 5,760 for 100 rate). Rye responded to lower seeding rates through increased tillering, which resulted in a similar stem density.

Table 2. Rye crimping date, biomass, carbon-to-nitrogen ratio and rye seeding date and rate across all six sites

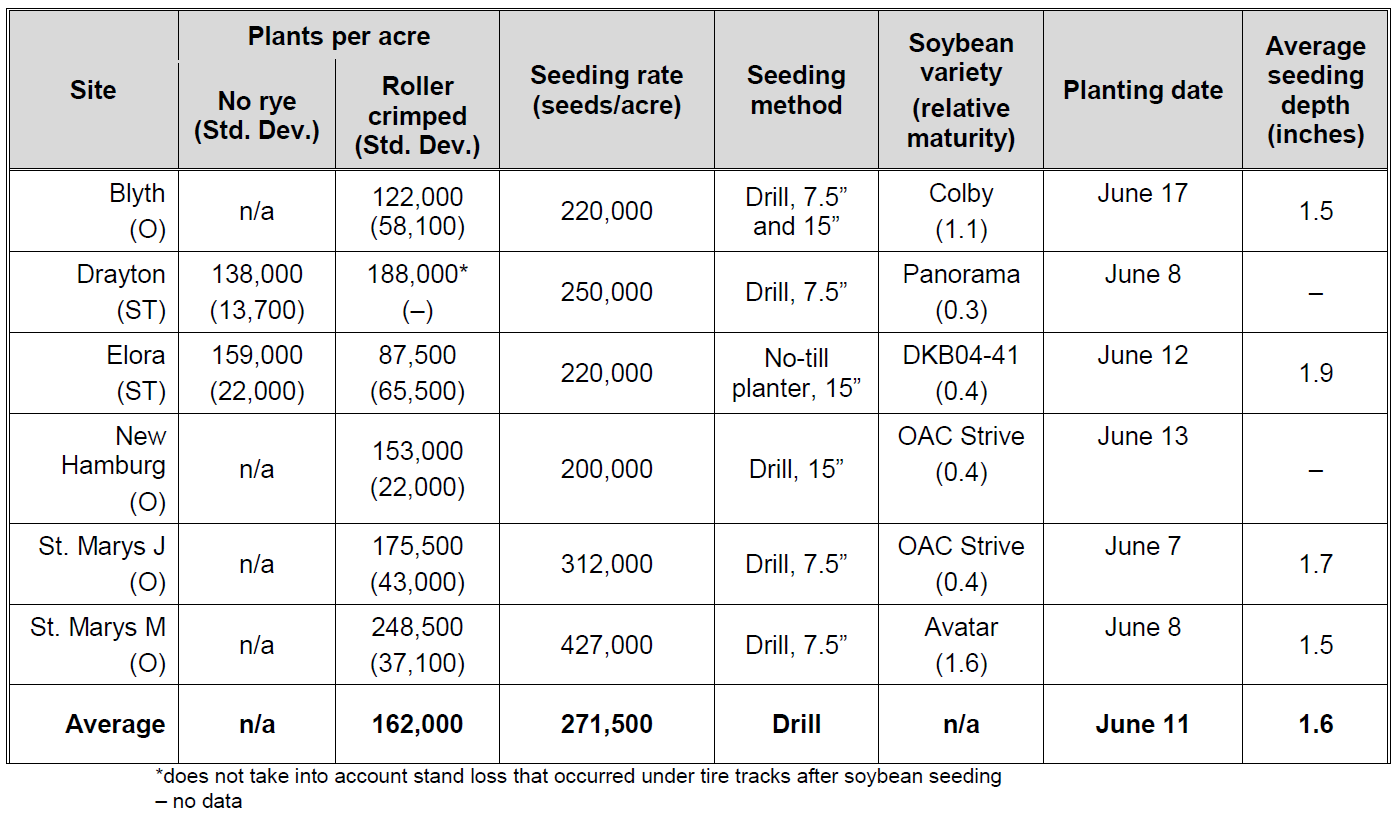

Soybean stands

Seeding soybeans to a sufficient depth, closing the seed slot and achieving an acceptable stand is critical to the success of the system. It is recommended to seed soybeans at a higher rate than normal, typically 225,000-250,000 seeds/acre. All sites were seeded at a rate greater than 200,000, with an average of 277,500 seeds/acre (Table 3). Farmer cooperators at the two St. Marys sites opted for much higher seeding rates, which resulted in thicker soybeans stands on average.

No-till drills were used to seed soybeans at all sites except Elora, where a no-till planter was used (Figure 5). Soybeans were seeded before crimping at the Drayton (Figure 5) and New Hamburg sites. Generally, it is recommended to use a modified planter, with sufficient down-pressure, cutting coulters and appropriate closing wheels for high residue. The drilled fields, on average, achieved acceptable stands; slot closure, however, was not achieved by any drill across five sites (Figure 6) due to moist conditions under the rye at seeding. Fortunately, ample rainfall after seeding across all sites ensured adequate germination and emergence.

Figure 5. Drilling soybeans into standing rye on June 8th at the Drayton site (left) and into roller crimped rye using a no-till planter on June 12th at the Elora site (right).

Table 3. Soybean population, seeding rate, method, variety, planting date and depth

Figure 6. Lack of seed slot closure at Drayton site as observed on June 18th.

The thinnest stands were observed at the Blyth and Elora sites. At Elora, this was likely due to surface compaction caused by the second crimping, which occurred on June 19th, seven days after soybean seeding. Seeds germinated but were not able to emerge underneath tire tracks (Figure 7) in nearly all replicates. At the Blyth site, the inability of the drill to cut through thick rye residue (see Figure 7) resulted in stand gaps. In situations where high rye biomass is achieved, sharp, well-maintained equipment is critical.

Figure 7. An example of where the no-till drill was unable to cut through rye residue and place the seed into the soil at the Blyth site (left). On the right, a compromised soybean stand in a roller crimped strip at Elora, as seen on July 10th.

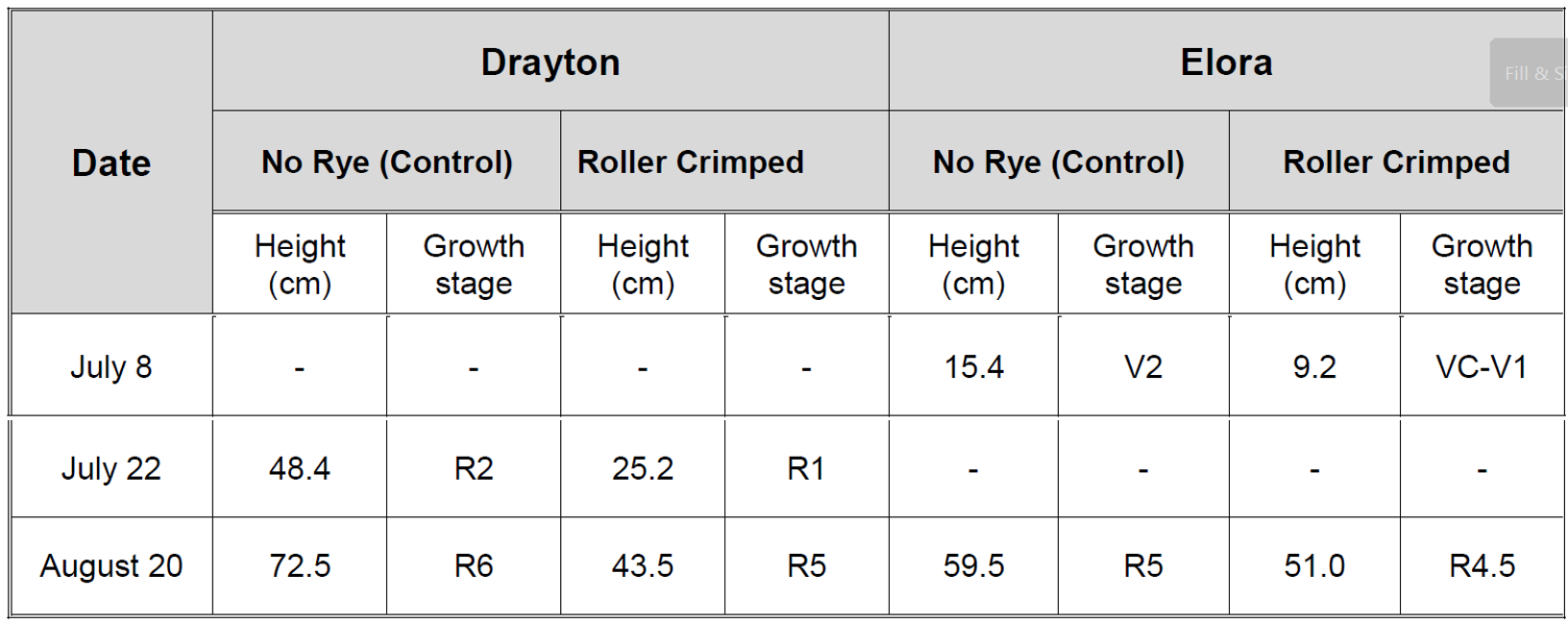

Soybean growth and development

At the strip-trial sites, on average, soybeans planted into roller crimped rye lagged one growth stage behind the no-rye control throughout the season. The difference was greater between treatments at the Drayton site, likely due to a thicker rye mulch and the fact that soybeans spent approximately three weeks under a standing rye canopy. By late August, the roller crimped soybeans at Elora were nearly the same height as those in the control strips (Figure 8); those at the Drayton site, however, remained about 40% shorter and only fully canopied in late August (Figure 9).

Table 4. Average soybean height and growth stage at various points throughout the season at the Drayton and Elora sites.

Figure 8. No-rye control strip (left) and soybeans planted into roller crimped rye (right) at the Elora plot on August 20th

Figure 9. Boundary between a no rye control strip with 30” soybeans and drilled, 7.5” no-till organic soybeans at Drayton site on July 22nd (left) August 20th (right)

Soil moisture and temperature

Spring

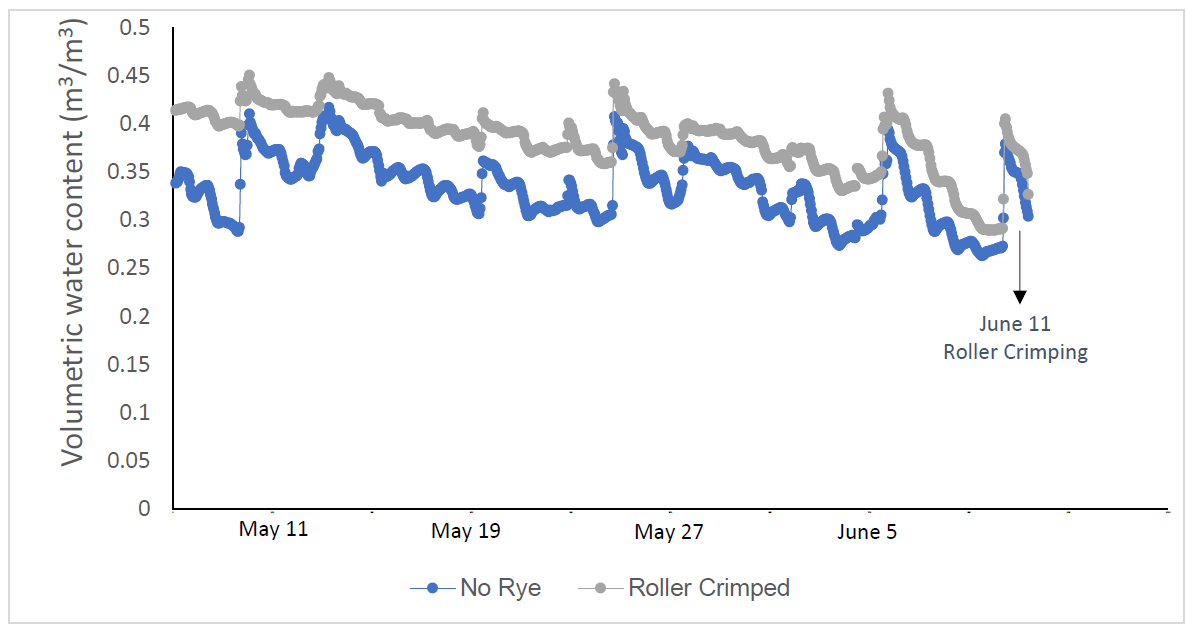

Soil moisture was measured at 2-inch depth, mid-row, in each of the treatments at Elora from late April until harvest. Figure 10 shows the differences in soil moisture from May 7th to June 11th. During this period, soil in the rye treatment was wetter than the no-rye control. The greatest difference in moisture occurred in early May and the gap lessened toward early June. By the date of crimping, soil moisture was only slightly higher in the crimped rye treatment.

The difference in soil moisture was likely due to reduced evaporation from the soil underneath the rye. As the rye grew rapidly and headed out, however, it began transpiring much larger amounts of water, which would have helped dry out the soil. In a dry spring, it is likely that the soil with the roller crimped rye would be drier than the no-rye soil at the time of planting.

Figure 10. Average soil moisture at 2-inch depth in no-rye control treatment (blue) and roller crimped treatment (grey) from May 7 to June 11, 2019

Summer

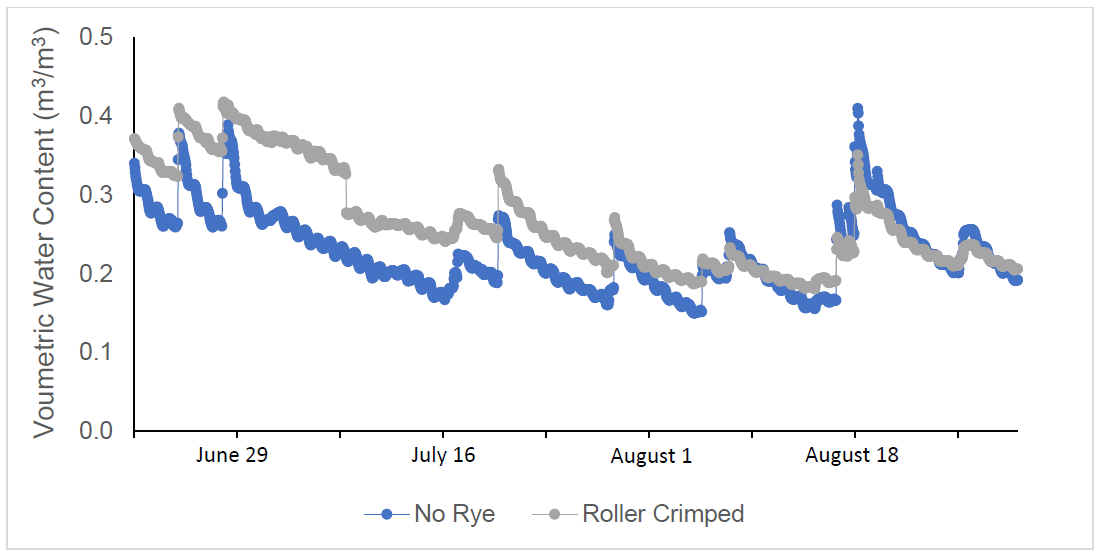

After planting (June 12), soil moisture levels remained higher under the roller crimped treatment (Figure 11). The rye mulch on the soil surface helped to reduce evaporation and maintain higher soil water content following rainfall events. This was important from June 29th through to July 17th, during which time there was no rainfall at Elora. As the season progressed and the soybeans canopied, the difference between treatments was reduced. By mid-August, there was no difference between treatments.

Figure 11. Average soil moisture at 2-inch depth in no-rye control treatment (blue) and roller crimped treatment (grey) from June 21 to August 31, 2019

Soil temperature

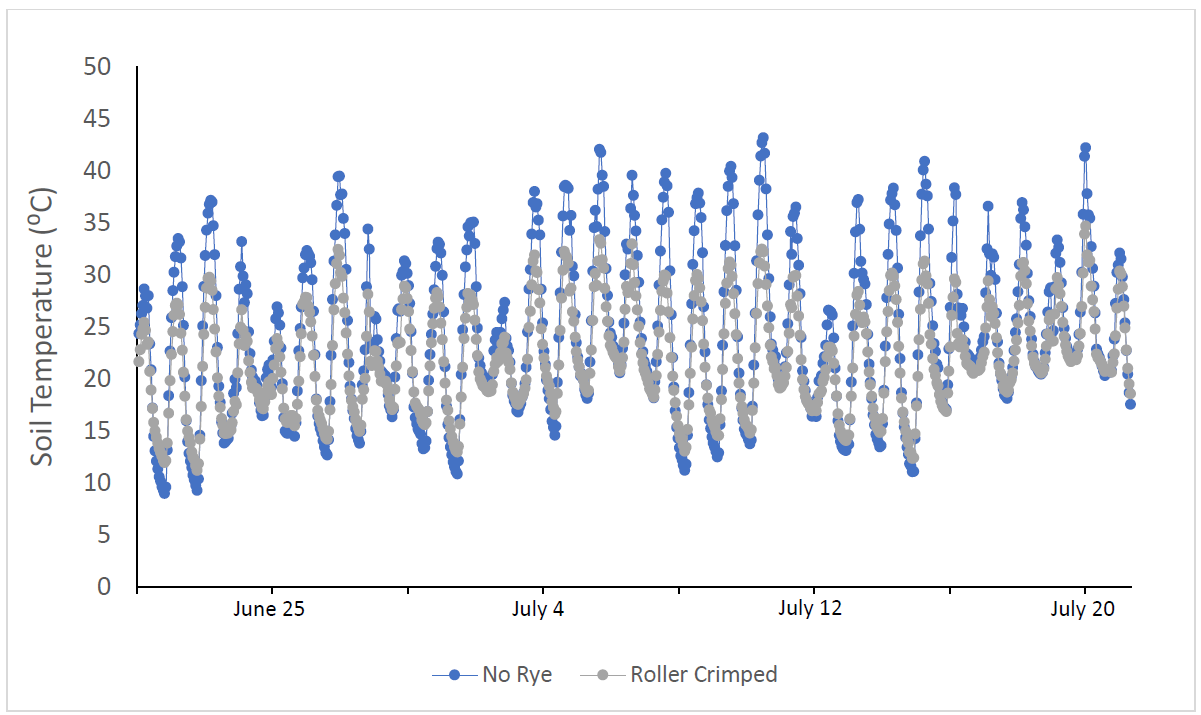

In the spring, the rye slowed the soil from warming compared to the no-rye control – daily maximum temperatures in late May and early June were 5-7⁰C lower. Throughout the summer, however, the rye mulch had a moderating effect on soil temperature. Soil in the roller crimped treatment had lower daily maximum temperatures and higher daily minimum temperatures than the no-rye control treatment (Figure 12). The soil temperature surpassed 40⁰C five times under the no-rye control but remained below 35⁰C throughout the hottest part of the season in the roller crimped rye treatment. This moderating effect may have helped to create a more favourable environment for early-to-mid season root growth as well as for soil microbial activity in the rye treatment.

Figure 12. Average soil temperature (⁰C) at 2-inch depth in no rye (control) treatment (blue) and roller crimped treatment (grey) from June 21 to July 21, 2019

Yield results

Strip trial sites

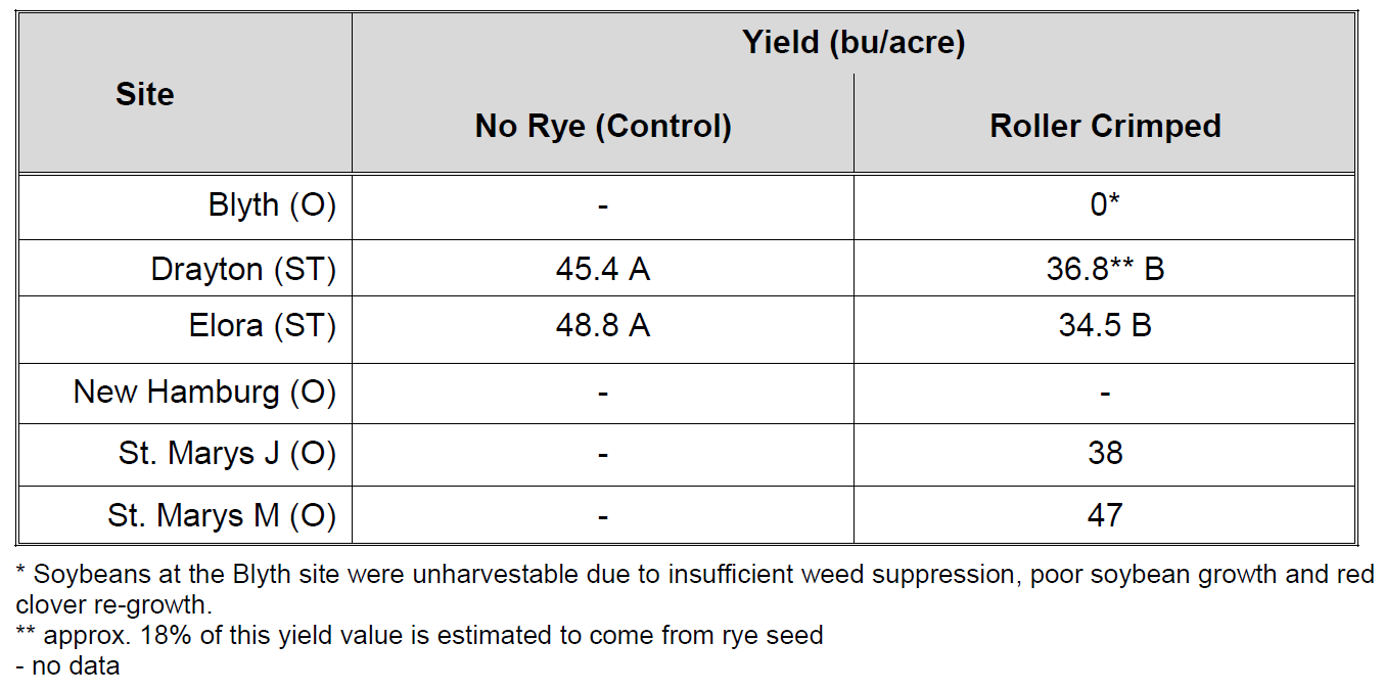

The yield difference between the tillage-based, 30” organic soybeans and the 7.5” no-till organic soybeans at the Drayton site was 8.6 bu/acre (Table 5). Given that the no-till soybeans were approximately half the height of the 30” soybeans and spent a full month – from seeding to crimping – under the canopy of the rye cover crop, this was a surprisingly small difference. The no-till soybean plants, despite their small size, had a comparable number of pods; however, they had smaller beans and fewer beans per pod. Viable rye seed also contributed to the yield of the no-till treatment – the cooperating farmers used it for hog feed.

At the Elora site, roller crimped soybeans yielded 14.3 bu/acre less than those in the no-rye control treatment. Although the difference in size and height of soybean plants between treatments was minimal, the poor soybean stand in the roller crimped treatment is believed to be the main contributor to the lower yield. A sub-90,000 soybean stand, planted on June 12th, likely was not able to compensate enough relative to the full stand in the no-rye control treatment. The mulch generally provided sufficient weed suppression through the critical weed-free period (V1-V3), though warm-season grasses emerged and grew later in the season and produced viable seed by harvest time.

Observational sites

Cover crop-based organic no-till yields ranged from unharvestable to 47 bu/acre at the observational sites (Table 5). A combination of factors resulted in an unharvestable field at the Blyth site, including: poor rye establishment in fall 2018, higher grassy weed pressure, late soybean planting (June 17th) and gaps in the soybean stand due to ineffective cutting of the rye mulch by the no-till drill. Sharper discs and a higher soybean seeding rate may have helped in overcoming some of these barriers.

At the two St. Marys sites, satisfactory weed suppression and soybean stands were achieved in both cases. At the St. Marys M site, despite low rye biomass (4,600 lbs/ac), the grower achieved an excellent soybean stand and good weed control through adaptive management. The farmer, who had several years’ experience with the system, decided to drill in narrow (7.5”) spacing instead using his planter and opted for a very high seeding rate (>400,000 seeds/ac). The two factors combined to create a vigorous and competitive soybean stand that smothered weeds. At the St. Marys J site, a higher soybean seeding rate helped to compensate for the challenges of seeding into a rye stand that was ~15% lodged due to high fertility. Soybean lodging was not an issue in either field.

Soybean maturity may also be an important factor in yield potential of the system. Despite being planted within one day of each other, the Group 1 soybeans at St. Marys M site out-yielded the Group 0 soybeans at St. Marys J site by 9 bu/acre. Soil conditions and fertility were believed to be as good or better at the St. Marys J site. Given that it is not viable to seed a winter cereal following organic no-till soybeans, opting for a longer-season variety may be an effective approach for maximizing yield in this system.

Table 5. Summarized yield results from all sites. Statistically significant differences are shown by different letters.

Summary

In this first of two years, cover crop-based organic no-till soybean production was evaluated at six different sites across southwestern Ontario. There were a range of outcomes, from an unharvestable site to one that out-yielded the 2019 provincial soybean average. At the strip trial sites, the no-rye control treatments out-yielded the roller crimper treatments in both cases – stand issues and delayed crimping are believed to be the main contributing factors. At other sites, including Blyth, insufficient weed suppression by rye was the biggest factor. Results at the St. Marys M site, however, showed what is possible with the system. Given the potential benefits of organic no-till soybean production, such as labour and fuel savings, erosion reduction and improved soil health, it is worth continued effort to make the system work.

Based on this season’s observations, the following lessons were learned:

- Select fields with low perennial weed pressure and decent background fertility

- Seed rye early and thick to achieve sufficient rye biomass

- Use well-maintained equipment to ensure good cutting of the rye mulch and placement of soybeans

- Seed soybeans at a high rate (e.g. minimum of 250,000 up to 300,000+ seeds/acre)

Next Steps

Five sites have been seeded to rye in the fall of 2019 to further evaluate cover crop-based organic no-till soybean production in the 2020 season. The trial will continue to evaluate the cover crop-based no-till system using best practices. The target soybean seeding rate for next year will

be 300,000 seeds per acre and longer-season soybean varieties will be grown. Also, several sites will compare the practice of seeding before crimping – with a target seeding date of early May and crimp date of early June – to seeding post-crimping in early June.

Visit the OSCIA tent at Canada’s Outdoor Farm Show in 2020 to see one of the sites and check Crop Advances in 2021 for the final report.

Acknowledgements

This project was supported by OSCIA Tier 2 project funding. Donations of cereal rye seed were generously made by Cribit Seeds and Thompsons Ltd. Thank you to the farmer cooperators who participated.

Project Contacts

For more information, contact Jake Munroe, Soil Management Specialist (Field Crops), OMAFRA at: jake.munroe@ontario.ca or 519 301 0548.